LCC SA Series Coil Straightener-Feeder

Forming the future for straightener/feeders

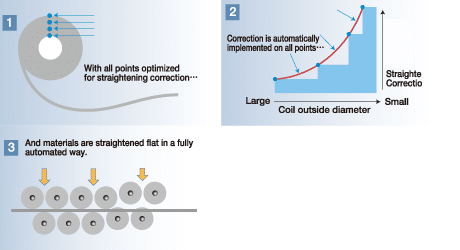

The straightening roll adjustment wheel has disappeared! Amada Press System has redefined press automation with the LCC SA coil straightening-feeding machine, featuring new technologies including the first ever Active Straightening Correction (ASC) mechanism.