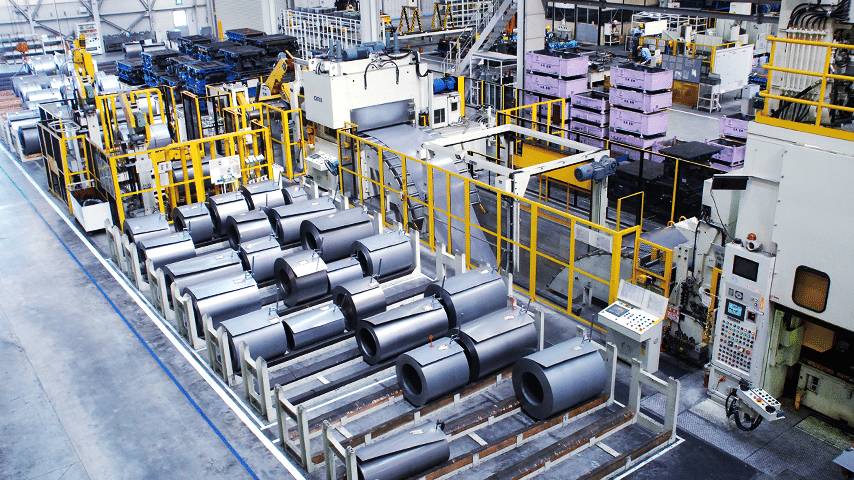

Large-Scale Coil Feeder Line

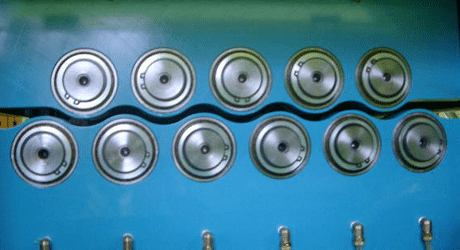

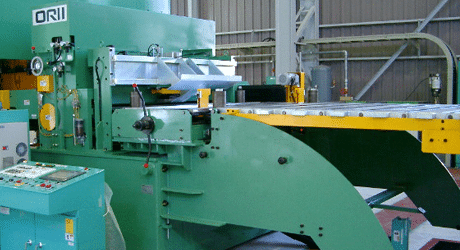

Amada Press System’s line of world standard large-scale feeders are designed to support today’s high-tensile steel with stock widths up to 1,900 mm (74″) and stock thicknesses up to 6.0 mm (0.236″). The Large-Scale series of coil feeder includes hands free coil setting, shearing capabilities, and rewinding of unwound stock. In addition to blanking presses, this technology produces cut-to-length lines.