RHQ/RHN 2-Axis Press Transfer System

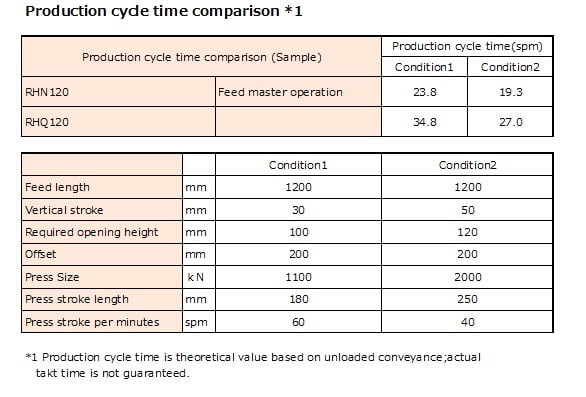

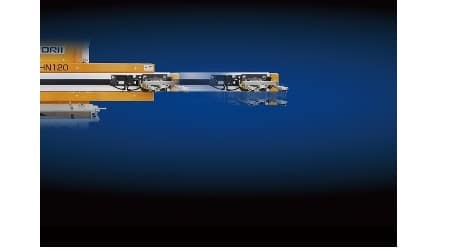

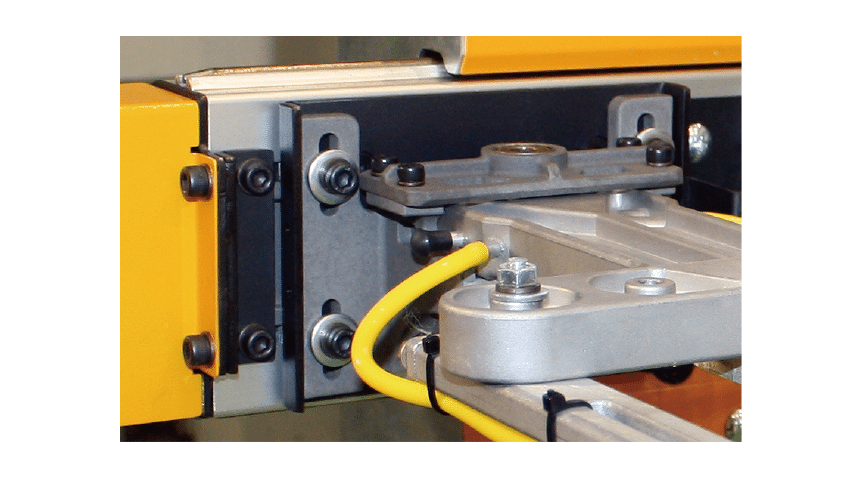

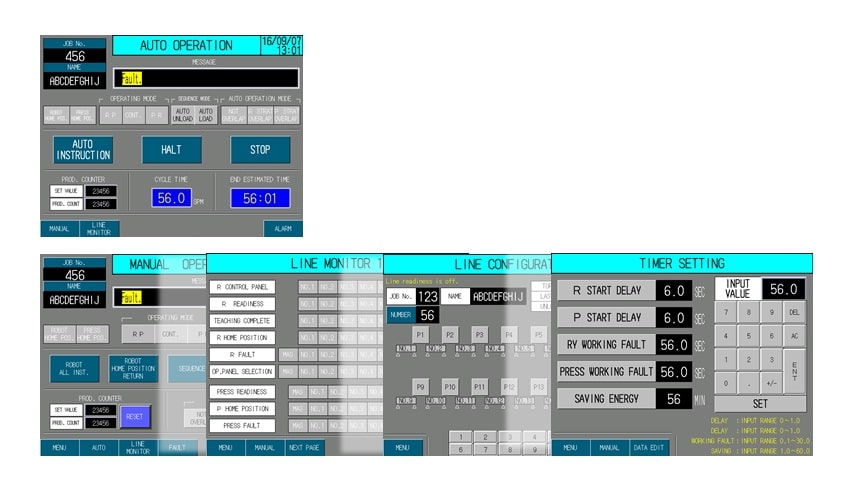

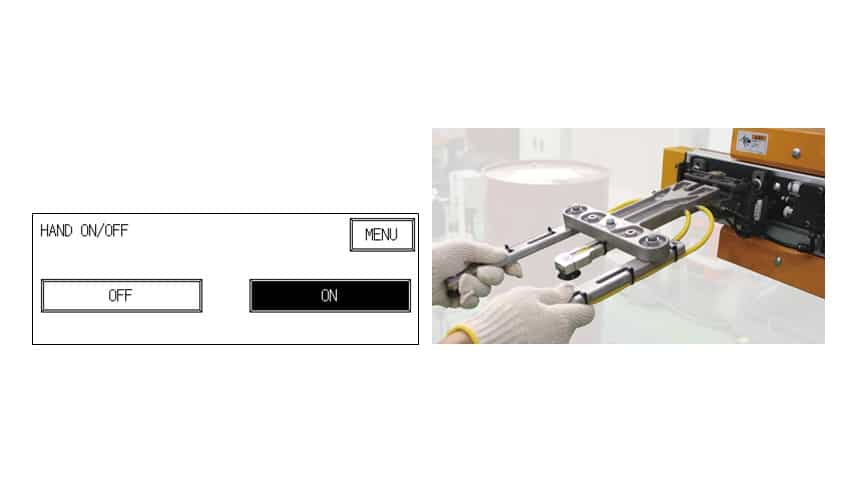

The RHQ and RHN press transfer systems offer best-in-class in transfer speeds and accuracy. The RHQ fully synchronizes with stamping presses via remote control panel, while the RHN offers the same capabilities with an overhead controller.